Is your OCT lying to you?

It is difficult to overestimate the importance of the OCT in eye care. After finding its initial applications in retinal imaging OCT quickly expanded to imaging of the optic nerve, lens, and anterior segment. Naturally, OCT also found multiple applications in specialty contact lens fitting. For scleral lenses OCT is now widely used to evaluate the lens edges, impingements, and clearances.

However, when using OCT for evaluating scleral lens thickness and vault, one must be careful. Many specialty contact lens fitters who routinely use OCT for evaluating corneal clearance will tell you that OCT measurements often overestimate the scleral lens vault. We recently encountered a similar effect, when the lens that was manufactured with a 300-µm central thickness was measured by an OCT to be 417-µm.

To understand the cause of this, one must consider the operating principle of the OCT. In an OCT the light is split into two beams, one of which, the measurement beam, is directed towards the eye and the other, the reference beam, is directed to a mirror inside the OCT device. The two beams are reflected and recombined, and a detector inside the OCT device measures the strength of interference between the two beams. The smaller the difference between distances traveled by the measurement beam and the reference beam, the stronger is the interference signal.

But there is a catch – because of some general relativity shenanigans, when light travels through a material of certain thickness, it thinks that the thickness of the material is larger than it really is. For example, light traveling through 1-inch of gas permeable polymer with a refractive index of 1.4 thinks that it traveled 1.4 inches, not just 1 inch. If you have two beams one going through a polymer material and another going through air, they will create interference on the detector when the beam in the air goes 1.4 times the distance of the beam in the polymer. Hence, unless your OCT manufacturer specifically corrects for the refractive index of the material, you will be overestimating your vaults and lens thicknesses by about a factor of 1.3 or 1.4 respectively.

To make the matters even worse, in order to properly calculate the correction factor, you also need to take into the account the magnification of the OCT signal by the front surface of the lens. [1] But in our calculation this value is rather small and simply multiplying the vault by the refractive index of saline (1.33) or the GP lens material (1.4) is sufficient to get a useful measurement.

Acknowledgements. We want to thank Dr. Obinwanne Chukwuemeka Jr (OD, FLVPEI, FAAO, FSLS) for a productive discussion on this topic and for pointing out the need for additional correction due to the lens magnification.

It is difficult to overestimate the importance of the OCT in eye care. After finding its initial applications in retinal imaging OCT quickly expanded to imaging of the optic nerve, lens, and anterior segment. Naturally, OCT also found multiple applications in specialty contact lens fitting. For scleral lenses OCT is now widely used to evaluate the lens edges, impingements, and clearances.

However, when using OCT for evaluating scleral lens thickness and vault, one must be careful. Many specialty contact lens fitters who routinely use OCT for evaluating corneal clearance will tell you that OCT measurements often overestimate the scleral lens vault. We recently encountered a similar effect, when the lens that was manufactured with a 300-µm central thickness was measured by an OCT to be 417-µm.

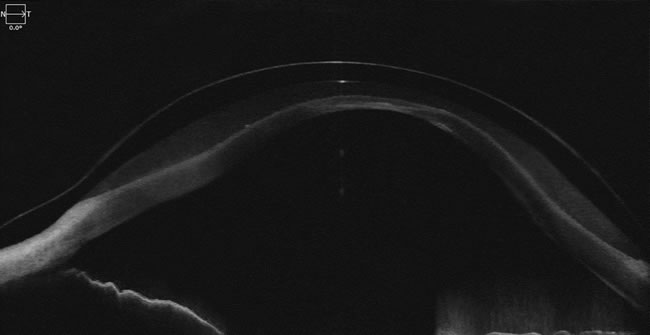

AS-OCT Image of Gaudi lens on the eye. Courtesy of Dr. Aaron Wolf, Austin Optometry Group.

To understand the cause of this, one must consider the operating principle of the OCT. In an OCT the light is split into two beams, one of which, the measurement beam, is directed towards the eye and the other, the reference beam, is directed to a mirror inside the OCT device. The two beams are reflected and recombined, and a detector inside the OCT device measures the strength of interference between the two beams. The smaller the difference between distances traveled by the measurement beam and the reference beam, the stronger is the interference signal.

But there is a catch – because of some general relativity shenanigans, when light travels through a material of certain thickness, it thinks that the thickness of the material is larger than it really is. For example, light traveling through 1-inch of gas permeable polymer with a refractive index of 1.4 thinks that it traveled 1.4 inches, not just 1 inch. If you have two beams one going through a polymer material and another going through air, they will create interference on the detector when the beam in the air goes 1.4 times the distance of the beam in the polymer. Hence, unless your OCT manufacturer specifically corrects for the refractive index of the material, you will be overestimating your vaults and lens thicknesses by about a factor of 1.3 or 1.4 respectively.

To make the matters even worse, in order to properly calculate the correction factor, you also need to take into the account the magnification of the OCT signal by the front surface of the lens. [1] But in our calculation this value is rather small and simply multiplying the vault by the refractive index of saline (1.33) or the GP lens material (1.4) is sufficient to get a useful measurement.

Acknowledgements. We want to thank Dr. Obinwanne Chukwuemeka Jr (OD, FLVPEI, FAAO, FSLS) for a productive discussion on this topic and for pointing out the need for additional correction due to the lens magnification.

- Ramasubramanian V, Glasser A. “Distortion Correction of Visante Optical Coherence Tomography Cornea Images,” Optom Vis Sci. 2015 Dec; 92(12):1170-81.